Side-Loop Photoreactors

From laboratory to tailor-made industrial production

The efficiency of photoreactors is of great importance in order to economically implement commercial production. Therefore, photoreactors must be tuned to a particular chemical process.

Once the type of photoreactor has been selected (e.g. side-loop reactor), all important parameters like the spectral emission, the lamp power, the optical path, the radiation flux and hydrodynamic behaviour of the solution, heat transfer, and possible gas distribution are important process parameters among others.

The high demand for equipment used in scale-up procedures of photochemical processes from laboratory to production scale, motivated Peschl Ultraviolet GmbH to develop a glass-type photoreactor system of industrial-size, enabling the optimization of a variety of different process parameters. In addition, the product series was expanded to include metal reactors for photochemical processes under pressure. These systems allow an easy configuration of efficient (side-loop) photoreactors.

Photochemical reactions (homogeneous and (micro)heterogeneous) in extreme high and low temperature ranges may be carried out. These state of the art photoreactor types are available with different optical paths and can be used with a variety of standardized options, e.g. in combination with optimized static mixers for gas/liquid and liquid/liquid heterogeneous media reactions, vacuum jackets for insulation and various sensors. All photoreactors are approved for explosion-proof operation and can be ATEX certified. A wide range of light sources in conjunction with electronic ballasts, safety-rated control and monitoring equipment completes the portfolio.

This series of photochemical reactors allows to configure and optimize photoreactors in industrial scale in the shortest possible time. The modular system, may be – at any time – easily adapted to changing process conditions. Different photochemical processes can be developed with minimized scale-up risks.

This example shows a typical laboratory setup called MPDS®. The photoreactor is installed in a standard-compliant and mandatory protective housing (photonCABINET). Next to the protective housing with photoreactor is the infrastructure for process development (controlCABINET) consisting of modular modules, which can be selected and exchanged according to requirements. The process controller with touch display is located in the upper module, with the online spectrometer and the ballast for operating the radiation source below.

This example is a side-loop photoreactor equipped with a cooling jacket. A medium-pressure immersion lamp with thermal decoupling is operated in the photoreactor, which is suitable for highly exothermic reactions. The glass components in contact with the product are provided with a special coating on the inside to prevent glass corrosion during fluorine reactions.

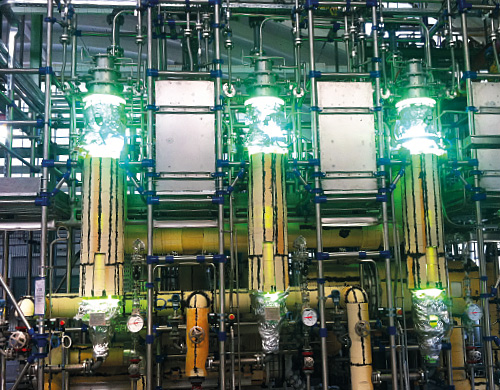

The photo shows part of a production plant with side-loop photoreactors in continuous operation for the production of artemisinin, an anti-malaria drug.

Large-scale side-loop photoreactors for industrial mass production can be ordered with lamps with up to 60 kW input power and are also available for low-temperature reactions down to -50°C. All immersion lamp systems are available for use in potentially explosive atmospheres and certified in accordance with the European standard (ATEX) as well as the North American standard (NEC 500).

Typical Processes

- Vitamins (e.g. pre-Vitamin D2 or D3 and derivatives by electrocyclic reaction or Vitamin A by cis-trans isomerization)

- Active pharmaceutical intermediates (API), e.g. synthesis of antimalarial drug, singlet oxygen reaction

- Fragrances (e.g. singlet oxygen reaction: Rose oxide

- Plant treatment intermediates (e.g. pinacols by photo-hydrodimerisation)

- Lubricants (e.g. Fomblin)

- Intermediates for diagnostics (e.g. by photo- bromination or photo-iodination)

- Chlorinated solvents (e.g. dichloromethane, chloroform, tetrachloromethane)

- Chlorinated intermediates for synthesis (e.g. benzylchloride, benzalchloride, methylchloride)

- Brominated intermediates for synthesis (e.g. substituted benzylbromides)

- Polymer and co-polymer specialities (photopolymerization in homogeneous (liquid), heterogeneous (liquid/liquid and liquid/gas (aerosols) media)

- Polymer functionalization (e.g. synthesis of API carriers, photo-halogenations, photooxidations in solid/liquid or sold/gas microheterogeneous media)

- Safety agents (e.g. odour additives for gases)

- Fluorinations, Sulfoxidations, Nitrosylations

What services we offer

- Engineering and supply of industrial-sized photochemical reactors

- Scale-up of your process from lab-size to industrial-size

- Scale-down of your process from industrial-size to mini-plant-size

- Photochemical process consultancy

- HAZOP studies for safe operation

- Commissioning support, on-site service

Technical Features

- Modulized toolbox system, fast to be configured

- High molecule exchange on the barrier surface

- Optimized residence time in the irradiated reactor volume

- Optimized gas injection and distribution due to special gassing systems

- Maximum pumping rates through the irradiated zones of the reactor

- Laminar and turbulent operation

- Ex-proof design of all components

- Up to 60 kW lamp power

- Gas-discharge, Excimer and LED lamps

- High cooling efficiency through the vessel wall or internal heat exchanger

- Hydrodynamic optimization by flow simulations (CFD)

- Process temperatures from -25°C up to 200°C

- Robust and reliable reactor designs for safe production

- Special materials of construction such as titanium, ceramics or special glass-lining for aggressive process conditions

Download

Photoreactors PDF

Please enter your name and Email address to generate a download link directly.

Any questions?

Please ask us