Process development and up-scaling can be easy

The implementation of a photochemical process from the laboratory to production scale is impossible without the prior investigation of fundamental photochemical process parameters. By using the MPDS®EVO in miniplant technology at the lab it is now possible to determine all photochemically relevant process parameters, such as the space-time yield, reaction kinetics, selection of suitable solvents, concentration and spectral absorption coefficient, optical path, etc. in a structured and reproducible way under supervision. In addition, different photochemical process methods can be compared and evaluated side by side. Only with the obtained fundamental process parameters, the feasibility and cost of photochemical processes can are assessed

(CAPEX / OPEX). By use of the unique easy-up-scaling radiation sources with stepless power regulation, which are part of the MPDS®EVO system, it is possible to select the correct application optimized industrial photoreactor out of the portfolio of Peschl Ultraviolet GmbH and thus, it is easy to transfer the process into commercial scale. Photochemical reactions which are already performed in industrial scale can be traced and afterwards optimized in detail in the laboratory (down-scaling). Using the reaction optimized and safe photoreactors of Peschl Ultraviolet, you are getting a highly efficient photochemical production plant with exceptional productivity.

All photochemically relevant wavelengths

We supply all types of lamps and doping as standard products. This means that we cover the entire spectral frequency range for the photochemistry in use, both  polychromatically or monochromatically. Innovative light sources such as xenon radiation sources or LEDs represent the cutting edge of technology in our photoreactors. We essentially supply the relevant spectral energy distribution data for all radiation sources.

polychromatically or monochromatically. Innovative light sources such as xenon radiation sources or LEDs represent the cutting edge of technology in our photoreactors. We essentially supply the relevant spectral energy distribution data for all radiation sources.

Extensive filter systems

Alongside standardised optical-cut-off filters and filter liquids, we also provide the option of insulating individual wavelengths for screening by means of band-pass filters. This makes it possible to determine their relevance for the photochemical reaction and recognise any unwanted secondary reactions.

Alongside standardised optical-cut-off filters and filter liquids, we also provide the option of insulating individual wavelengths for screening by means of band-pass filters. This makes it possible to determine their relevance for the photochemical reaction and recognise any unwanted secondary reactions.

Choose the appropriate standard photoreactor

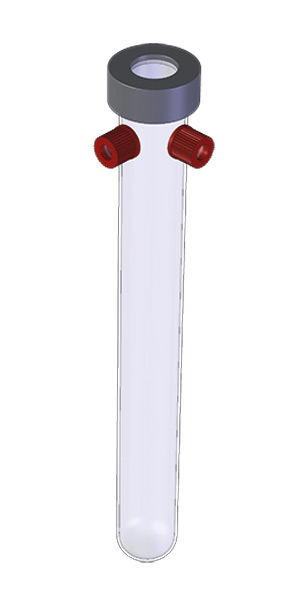

From batch to semi-batch through to conti-flow operation, we supply the entire range as standard photoreactors. This includes side-loop photoreactors, falling-film photoreactors, agitated photoreactors and plug-flow photoreactors. Depending on the application, you can choose from photoreactors with a volume of 2 ml to 5000 ml for laboratory trials.

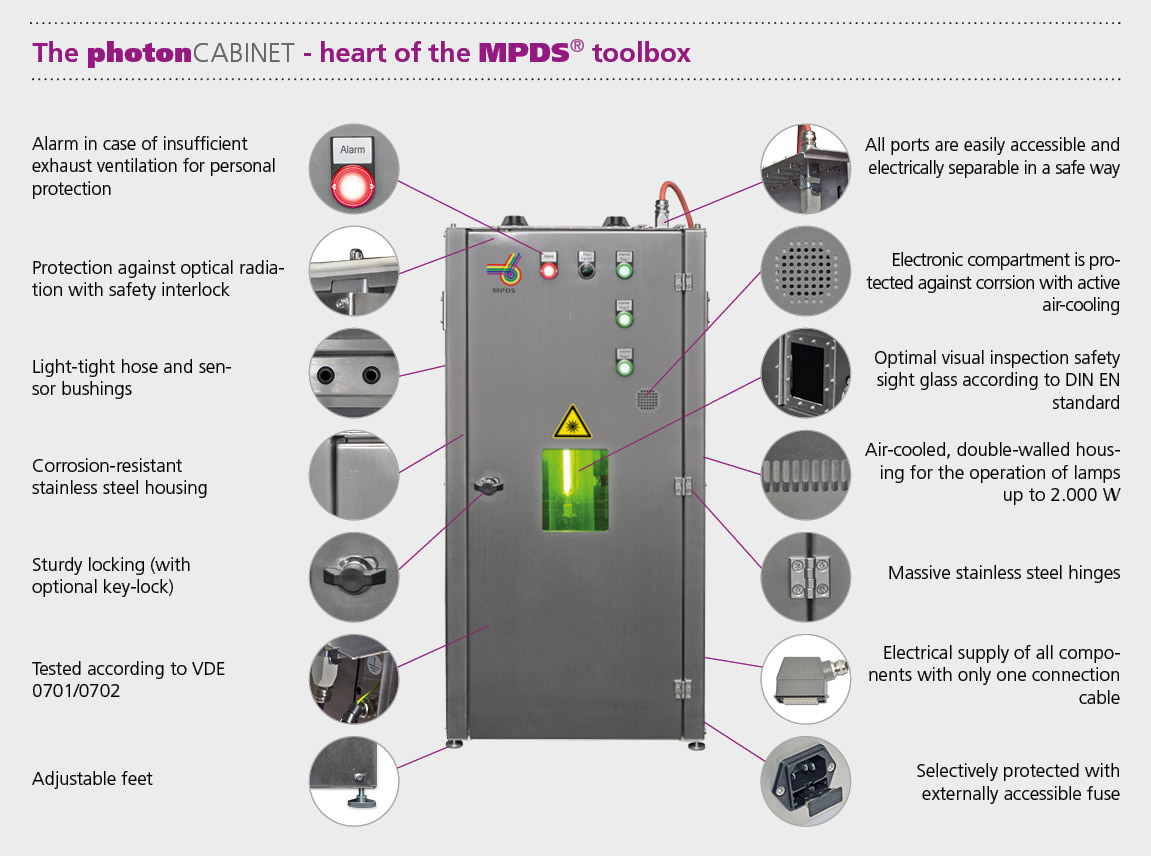

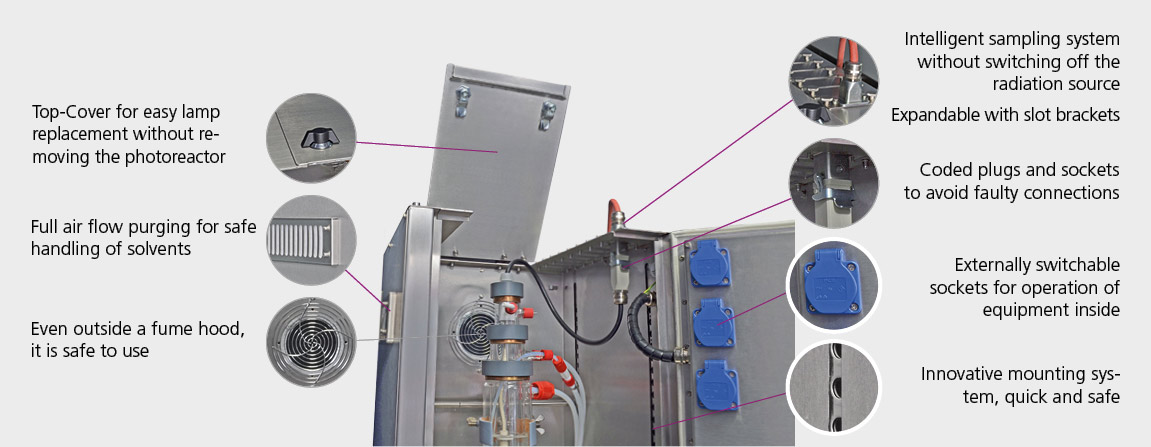

Safe to operate and yet practical to use

Use of protective casing is compulsory so as to comply with the legal industrial safety requirements. It is completely safe to perform photochemistry in the photonCABINET  (safety cabinet) and yet still practical. Special attention was paid to simple sampling and the uncomplicated insertion of sensors and actors such as stirring tables and dosing pumps. For example, encoded connectors ensure the correct electrical connection. The standard photoreactor systems are supplied fully wired and can be used immediately. With a footprint of 472 x 475 mm only, the system takes little space on the bench and still fits into a standard fume hood.

(safety cabinet) and yet still practical. Special attention was paid to simple sampling and the uncomplicated insertion of sensors and actors such as stirring tables and dosing pumps. For example, encoded connectors ensure the correct electrical connection. The standard photoreactor systems are supplied fully wired and can be used immediately. With a footprint of 472 x 475 mm only, the system takes little space on the bench and still fits into a standard fume hood.

Modular system

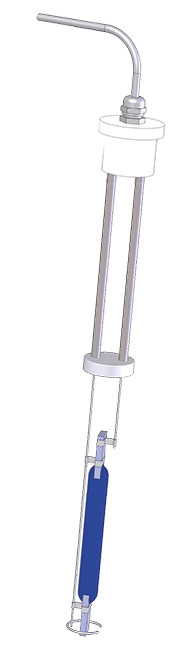

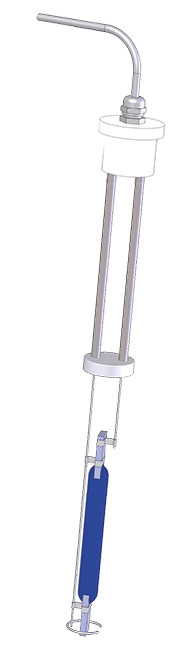

Photoreactors, cladding tubes and radiation sources are compatible with each other in the modular system and are therefore interchangeable. Application-optimised  photoreactors can be exchanged cost-efficiently, while the lamps and cladding tubes can be retained. By freely positioning the radiation sources in the cladding tube using the innovative high-tension mechanism, it is possible to use the components in a range of different sized photoreactors. An extensive product range of perfectly matching components, such as chemically resistant process and metering pumps, agitators, various sensors – e.g. for flow, temperature, pH / redox – as well as jacketed vessels are available in the modular system. Thus we offer a customizable and expandable process development system that you can use right away.

photoreactors can be exchanged cost-efficiently, while the lamps and cladding tubes can be retained. By freely positioning the radiation sources in the cladding tube using the innovative high-tension mechanism, it is possible to use the components in a range of different sized photoreactors. An extensive product range of perfectly matching components, such as chemically resistant process and metering pumps, agitators, various sensors – e.g. for flow, temperature, pH / redox – as well as jacketed vessels are available in the modular system. Thus we offer a customizable and expandable process development system that you can use right away.

Automated process development

The MPDS®EVO is equipped with the intelligent processCONTROL PLC-system and operated via the integrated touch panel.

In addition to the manual control of each individual aggregate, experiments can be performed in automatic mode, following a systematic sequence. This avoids errors and quickly leads to reproducible results.

In addition to the manual control of each individual aggregate, experiments can be performed in automatic mode, following a systematic sequence. This avoids errors and quickly leads to reproducible results.

Precise spectral measurement

The determination of the spectral characteristics plays the most important role in connection with the chemical reaction. Therefore, we provide flexible 'plug and play' photo-spectrometer, spectralradiometer and radiometer for precise online measurement. All photoreactors of the MPDS® toolbox are equipped with a standardized measuring point. Acquisition of the measurement values and their storage in a database are realized by an 'Windows 7 Embedded' PC with touch display, which is built into the spectro rack module and ready for operation. The data can be easily exported via USB for further revision.

The determination of the spectral characteristics plays the most important role in connection with the chemical reaction. Therefore, we provide flexible 'plug and play' photo-spectrometer, spectralradiometer and radiometer for precise online measurement. All photoreactors of the MPDS® toolbox are equipped with a standardized measuring point. Acquisition of the measurement values and their storage in a database are realized by an 'Windows 7 Embedded' PC with touch display, which is built into the spectro rack module and ready for operation. The data can be easily exported via USB for further revision.

Thermal decoupling decides

Alongside cold radiation sources, a sophisticated, modular cladding tube system is available for the thermal decoupling of the lamp from the reaction medium.  The innovative MPDS® screwing system prevents glass fastening elements from caking and can be applied with a maximum pressure of 0.5 bar. The diameters of the cladding tubes are optimised for photochemical reactions. Easy to clean thanks to fully demountable cladding tubes instead of double wall sleeves that are merged together, perfectly suited to CIP cleaning.

The innovative MPDS® screwing system prevents glass fastening elements from caking and can be applied with a maximum pressure of 0.5 bar. The diameters of the cladding tubes are optimised for photochemical reactions. Easy to clean thanks to fully demountable cladding tubes instead of double wall sleeves that are merged together, perfectly suited to CIP cleaning.

We will not leave you alone!

In addition to our turnkey process development systems, profound, scientifically substantiated consultancy services in the field of applied photochemistry might be required as a service. Together with our cooperation partner 'Oliveros Consulting' (Prof. E. Oliveros and Prof. A.M. Braun), we are able to transfer comprehensive and detailed knowledge of photochemical process technology and offer the assistance during your process development phase on advisory basis upon request.

Safety & Functionality

The MPDS®EVO Set includes the photonCABINET which is a double walled, light-proof protective cabinet made of stainless steel. I fulfills the legal requirements for personal safety agains optical radiation and protects surrounding materials against aging. The photonCABINET it is the only product on the market that meets the high requirements of the applicable standards, is CE compliant and also practicable and functional for operators. The necessary measures implemented for having a safe and functional product are well designed and protected by international patents.

UV radiation is harmful to eyes and skin and can cause irreparable personal injury. Furthermore materials in the ambient exposed to the UV radiation, will undergo an accelerated aging and can be destroyed. Medium pressure radiation sources have a surface temperature of up to 850° C and operate with lethal high voltage. Solvents may not present a explosion hazard for the user. The operation of photoreactors without optical protective device equipped with safety lock (aluminum foil, acrylic glass) is not allowed since the related normative standard was becoming mandatory (01.10.2013). In addition the risk analysis in accordance with EN ISO 12100 confirm, that an operation without safety cabinet is no longer sufficient and does not meet the requirements to protect employees by the owner / operator of the lab, who can be fully accountable and responsible for personal injury.

Therefore photoreactors of the MPDS® modular system always come along initially with the light-proof protective cabinet, which moreover provide the electrical power to the electronic power supplies for operating the radiation sources. Photochemical experiments are therefore absolutely safe. The unique photonCABINET is practicable, easy to use and inexpensive to purchase.

MPDS®EVO AOP

MPDS®EVO Falling film

MPDS®EVO Side Loop

MPDS®EVO Batch for liquids with low transmission

MPDS®EVO Batch for liquids with high transmission

MPDS®EVO Plug-Flow with LED lamp

MPDS®EVO Plug-Flow with Medium pressure lamp

nova®LIGHT TQ1000

Medium pressure

nova®LIGHT TLED100

High power LED

nova®LIGHT TLP15

Low pressure

nova®LIGHT FLED400

Flat-LED

nova®LIGHT FMP250

Flat-Medium pressure

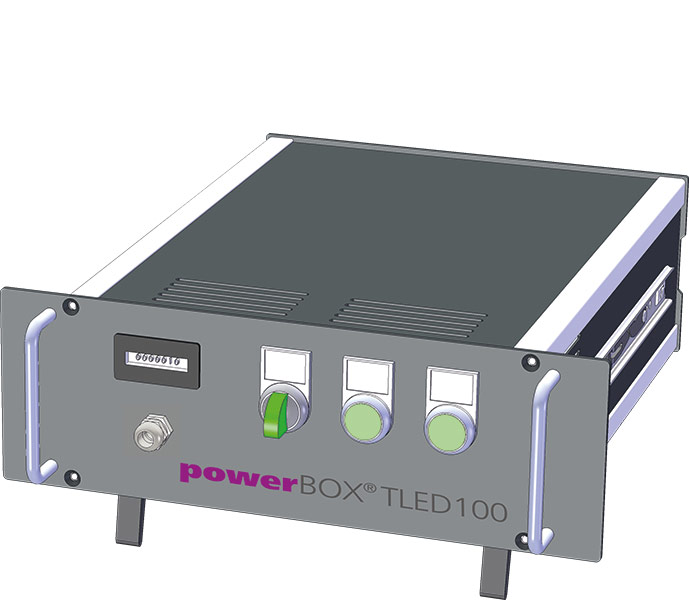

powerBOX

TQ1000

powerBOX

TLED100

powerBOX

TLP15

powerBOX

FLED400

powerBOX

FMP250

spectroSENSE

S200/1000

thermoCONTROL 100

thermoSCONTROLL 2000

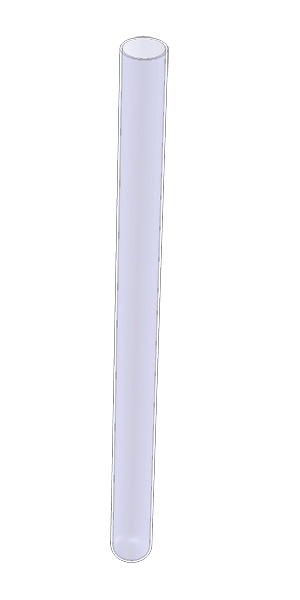

HR1-L

Quartz glass,

Borosilicate glass

HR2-L

Quartz glass,

Borosilicate glass

HR3-L

Quartz glass,

Borosilicate glass

Cut-off filter tubes

HR4-L

Quartz glass,

Borosilicate glass

Download

MPDS-EVO PDF

Please enter your name and Email address to generate a download link directly.

Any questions?

Please ask us